By Chris Pennucci

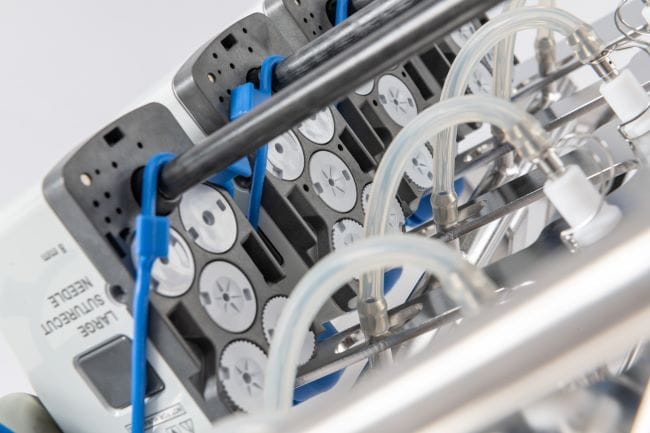

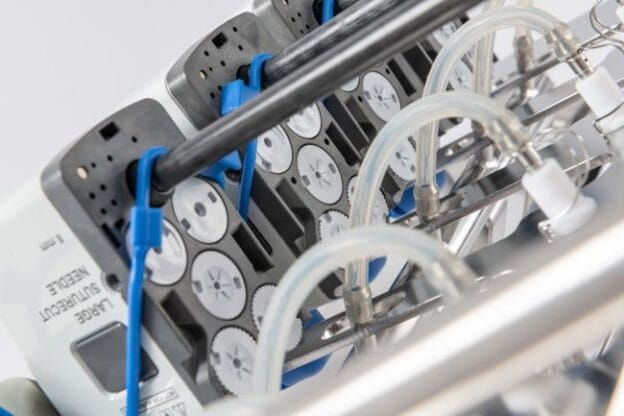

Seventy eight percent of U.S. surgeons expressed interest in utilizing robotic assisted surgical (RAS) technologies with only 53% currently using this technology.1 This interest is driving growth in the number of RAS procedures, expansion of the types of procedures supported by RAS, and the manufacturers of surgical robotic equipment. Sterile processing departments must adapt to the increasing volume and complexity of RAS instrumentation reprocessing.

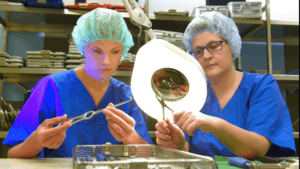

Correct reprocessing of RAS instrumentation is critical to maximizing usage of limited equipment and successful patient outcomes. Proper training is vital for success and begins with a good sterile processing preceptor.

Learning Objectives

- Identify traits of a good preceptor.

- Considerations when training staff on RAS instruments.

- Establish a plan for staff when they are working on their own.

About the Author

Chris Pennucci, BS, CRCST, CER is a Clinical Education Specialist for STERIS. He has been in the sterile processing field for 13 years as a technician, department coordinator, and department manager. Chris is also the past president of the Northern New England Chapter of HSPA. He holds certifications as a CRCST and CER and is a member of HSPA, AORN, SGNA, and APIC.

Critical Connections: Improving SP and OR Synergy

Critical Connections: Improving SP and OR Synergy  Sterilization Quality Control: Your Path to Protecting Your Patients

Sterilization Quality Control: Your Path to Protecting Your Patients  Ensuring Success: Become a Preceptor for Robotic Assisted Surgery Instruments in the Sterile Processing Department

Ensuring Success: Become a Preceptor for Robotic Assisted Surgery Instruments in the Sterile Processing Department  Lost in Translation: Ethical Dilemmas in Medical Manufacturing Instructions

Lost in Translation: Ethical Dilemmas in Medical Manufacturing Instructions  What Sterile Processing Should Know About Multidrug-Resistant Organisms (MDRO)

What Sterile Processing Should Know About Multidrug-Resistant Organisms (MDRO)  Making the Right Choice for Sterile Processing Consumable Stock Outages

Making the Right Choice for Sterile Processing Consumable Stock Outages  UV-C Disinfection Technologies: How it works and what are the current applications for health care settings

UV-C Disinfection Technologies: How it works and what are the current applications for health care settings  The Differences Between Peracetic Acid High-level Disinfectants and Sterilants

The Differences Between Peracetic Acid High-level Disinfectants and Sterilants  The Mystery of Bowie & Dick: Alterations in the Vacuum on Your Sterilizer Throughout the Year

The Mystery of Bowie & Dick: Alterations in the Vacuum on Your Sterilizer Throughout the Year  Meeting the Challenges of Endoscope Reprocessing and Documentation

Meeting the Challenges of Endoscope Reprocessing and Documentation  Education Nation: Sterile Processing Quality Management Systems

Education Nation: Sterile Processing Quality Management Systems  Product testing: The overlooked 4th pillar of a robust sterilization process monitoring program

Product testing: The overlooked 4th pillar of a robust sterilization process monitoring program  Importance of Water Quality for Medical Device Reprocessing

Importance of Water Quality for Medical Device Reprocessing  Mechanical Cleaning Safety: A Tale of Two Sides

Mechanical Cleaning Safety: A Tale of Two Sides  Sterilization Choices for the SPD

Sterilization Choices for the SPD  When Is Disposable the Right Choice for SPD?

When Is Disposable the Right Choice for SPD?  Education Nation: Sterile Processing Leadership Planning Sessions

Education Nation: Sterile Processing Leadership Planning Sessions  How Safe Is Your Sink?

How Safe Is Your Sink?  Sterile Processing Education – The balancing act between documentation and application

Sterile Processing Education – The balancing act between documentation and application  Moisture Absorption Devices….No This Is Not a Wet Pack Article

Moisture Absorption Devices….No This Is Not a Wet Pack Article  Positive Biological Indicators

Positive Biological Indicators  Washer disinfector release for use after maintenance

Washer disinfector release for use after maintenance  Beyond the visual: The importance of quality cleaning verification programs

Beyond the visual: The importance of quality cleaning verification programs  Education nation: Creating Sterile Processing Department SOPs

Education nation: Creating Sterile Processing Department SOPs  Cross out cross contamination in endoscope processing

Cross out cross contamination in endoscope processing  What’s new in AAMI ST79:2017? A review

What’s new in AAMI ST79:2017? A review  Healthcare soils 101: Identifying and removing them

Healthcare soils 101: Identifying and removing them  Expiration dating in the SPD

Expiration dating in the SPD  The Science of Speed

The Science of Speed  The fantastic four: Sterile processing, operating room, quality and education

The fantastic four: Sterile processing, operating room, quality and education  Ugh! Another wet pack. What’s a technician to do?

Ugh! Another wet pack. What’s a technician to do?  Sterilization quality control: Validation, routine monitoring go hand in hand

Sterilization quality control: Validation, routine monitoring go hand in hand  Manual cleaning – The critical human element

Manual cleaning – The critical human element  Water for cleaning medical devices

Water for cleaning medical devices  Can you afford to ignore obsolescence?

Can you afford to ignore obsolescence?  Automatic Equipment and Productivity in a Sterile Processing Department

Automatic Equipment and Productivity in a Sterile Processing Department  External Transport of Medical Devices

External Transport of Medical Devices  Troubleshooting Washer-Disinfector Performance

Troubleshooting Washer-Disinfector Performance  Understanding Bowie-Dick Testing: Purpose and Usage in Daily Sterilization Practice

Understanding Bowie-Dick Testing: Purpose and Usage in Daily Sterilization Practice  Understanding the Key Features and Benefits of Mechanical Cleaning Tools: Ultrasonic Baths, Water Guns, and Washer-Disinfectors

Understanding the Key Features and Benefits of Mechanical Cleaning Tools: Ultrasonic Baths, Water Guns, and Washer-Disinfectors